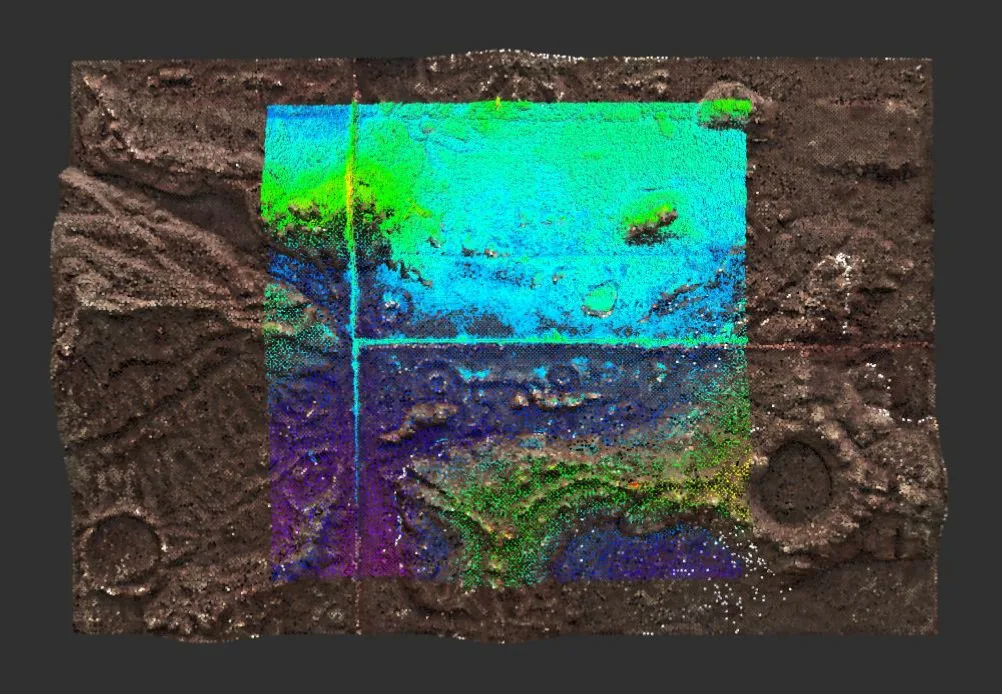

Although the Moon is only 384,400 km away from us, we know surprisingly little about it. It is possible to observe its facing side from Earth, but the data are of limited scientific value. It is therefore necessary to get a picture of the situation on site. This is usually done by flying or driving probes or rovers over the surface and mapping it. With regard to a permanent human presence on the Moon, one of the key issues is the location of resources. Lidar (Light Detection and Ranging or Light Imaging, Detection and Ranging) – a method of optical distance and velocity measurement – is used to obtain the most accurate data possible. Unlike radar, lidar uses laser waves instead of radio waves.

DCUBED prevails against US top dog

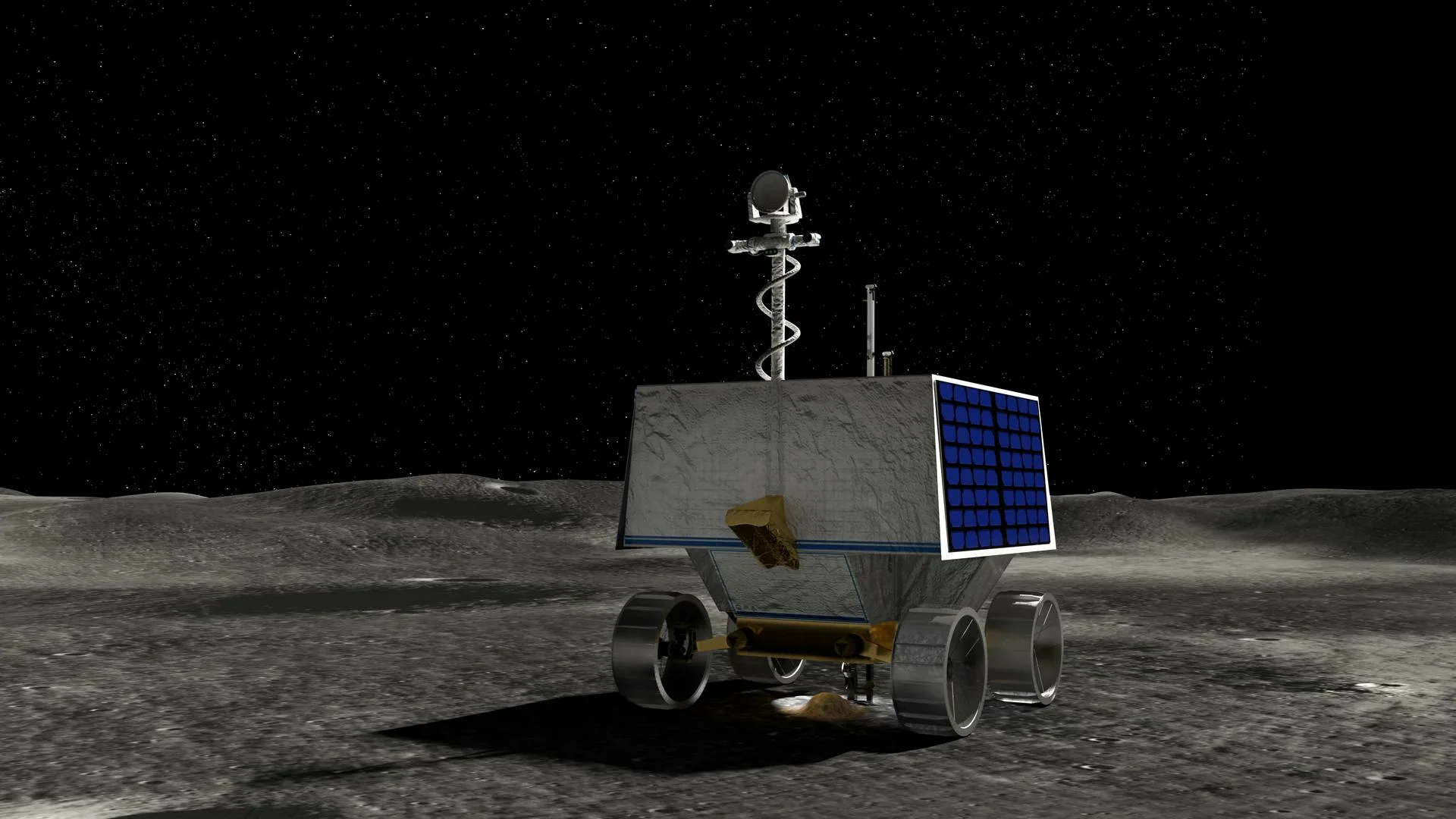

NASA’s Goddard Space Flight Center (GSFC) plans to equip rovers for future lunar missions with lidar. The Space Qualified Rover Lidar (SQRLi) project will use a space-qualified laser scanner mirror. In a support project for SQRLi, GSFC selected the German NewSpace company DCUBED to provide the necessary actuators. DCUBED initially emerged as the frontrunner and ultimately the winner of the waiver and procurement process. The Germering-based company finally outbid a local supplier from the US. Nevertheless, it will be some time before DCUBED’s so-called nano-pin pullers are used on the moon. For now, the GSFC is procuring a total of 25 technical samples of the laser mirror.

SQRLi for future missions to the Moon

The SQRLi is a LIDAR test device that was developed for rover-based missions. It is characterized by its ability to operate in low light conditions, such as those found in a lunar crater, and has a range of over 35 meters. The laser scanner assembly is designed to withstand more than a year of continuous use in the presence of lunar dust. As part of the support project, it was necessary to be able to supply a pin-puller that could be reset for test purposes. Criteria that DCUBED’s in-house development met with bravura. This is possible because DCUBED consistently relies on the use of shape memory materials. This makes it possible to produce components of small size and mass that are also highly reliable.